The grinding media and ball production industry is undergoing a significant transformation in 2025. With advancements in materials science, manufacturing technologies, and evolving customer demands, businesses must stay ahead of the curve to remain competitive. At STR Industries, we’ve been at the forefront of this industry for over 30 years, delivering high-quality grinding media and…

The Critical Importance of Product Availability in an Uncertain Global Market

In a world where supply chains connect continents, ensuring product availability is no longer a back-office concern—it’s a cornerstone of business success. For companies and consumers alike, consistent supply means more than stocked shelves; it fosters trust, drives value, and sustains operations in the face of economic and political turbulence. The global market has faced…

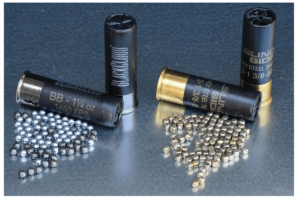

Advancements in Steel Shot: STR Industries Revolutionizes Shotgun Ammunition

In the world of shotgun ammunition, steel shot has emerged as a popular alternative to traditional lead shot. This shift is driven by increasing environmental awareness and regulations surrounding lead toxicity, particularly in waterfowl hunting. Steel shot offers a cleaner and more sustainable option, but it also comes with unique challenges and opportunities for improvement….

The Science Behind Burnishing Media | Vibratory Burnishing Explained

Burnishing is an essential process in manufacturing, transforming metal parts into smooth, polished components with enhanced durability. By cleaning, smoothing, and removing imperfections, burnishing prepares metal surfaces for optimal performance. Among the many methods, vibratory burnishing with steel media is one of the most effective techniques to achieve superior results. What is Vibratory Burnishing? Vibratory…

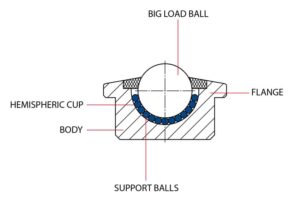

Elevating Efficiency: STR Industries’ High-Precision Transfer Units

Exploring STR Industries’ Transfer Units: Precision at the Core In today’s fast-paced industrial and manufacturing environments, precision and efficiency are not just desirable—they’re essential. At STR Industries, these principles drive the design and production of high-quality transfer units. Whether optimizing workflow in an assembly line or facilitating smooth material handling, STR’s transfer units deliver unmatched…

Overstock Opportunity: Bulk Sale of 27/32″ Chrome Steel Balls G25 – Ideal for Grinding Media & Bearings

Exclusive Overstock Alert: 27/32″ Chrome Steel Balls G25 in Bulk Looking for premium-quality steel balls for your industrial needs? Your search ends here! We’re offering an overstock sale on 27/32″ Chrome Steel Balls G25, perfect for grinding media and bearing applications. With 72,000 pieces available, this is your chance to secure a bulk supply at…

How Steel Balls Keep Sliders Moving Smoothly in Industrial Machines

In the world of industrial machinery, sliders play a key role in keeping parts moving with precision. To make sure sliders perform at their best, steel balls are often used. These small components help reduce friction and keep things moving smoothly, even under heavy loads. That’s why you’ll find them in everything from conveyor systems…

The Importance of High-Precision Steel Balls in U.S. Automotive and Industrial Applications

Steel balls are essential in modern manufacturing and automotive systems, providing critical support for components like bearings, CV joints, and conveyor systems. Without precision steel balls, the efficiency of various machinery would decrease dramatically, leading to increased maintenance and shorter equipment life. STR Industries manufactures high-precision steel balls that meet the most stringent standards. From…

The Versatile Power of 5/16 Carbon Steel Balls: Your Perfect Slingshot Ammo

Slingshot enthusiasts understand that choosing the right ammo is crucial for accuracy, power, and durability. Whether you’re a seasoned shooter or just getting started, finding the right ammunition can make all the difference. That’s where 5/16 carbon steel balls from STR Industries come into play. Built for performance, these steel balls are becoming the go-to…

Spotlight on 2 mm Chrome Grinding Balls: Precision in Every Grind

At STR Industries, we believe that precision, durability, and quality are the backbone of any successful grinding operation. This month, we’re putting the spotlight on our 2mm Chrome Grinding Balls, available in stock in the United States and ready for delivery. These meticulously engineered balls are designed to optimize performance in a wide range of…