Design and Application of Our Ball Transfer Units

Ball Transfer Units

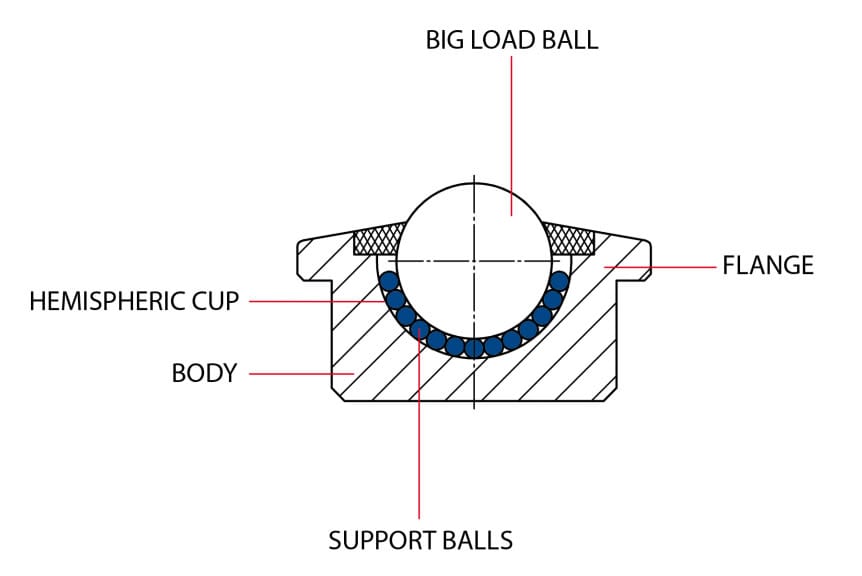

At STR Industries, we provide high quality ball products at competitive prices, including ball transfer units. Ball transfer units consist of a ball mounted within a housing, surrounded by smaller ball bearings that support and allow for the rotation of the center ball in any direction. They facilitate the movement of heavy loads in industrial applications, such as in warehouses, packaging and handling facilities, manufacturing shops, and distribution centers.

All balls are ground and heat treated; they start moving when the main big ball (which is made of hardened steel, stainless steel or plastic) rolls, to let it move with the lowest possible friction and guarantee a regular movement. This kind of construction allows moving with small effort any kind of heavy material, whose surface is plain, smooth and rigid enough.

Friction is extremely reduced and a smooth movement is provided at a speed of 2m/sec. In this way, very heavy loads can be easily moved.

Our production range includes different kinds of ball transfer units, starting from a main supporting ball’s dimension of 8mm up to a maximum of 90 mm in steel, stainless steel or polyacetal plastic material, and loading capacities from 15 kg to 2000 kg. Basically there are two kinds of products: Machined Heavy Duty units (studied for heavy shock loads and long life applications), and Pressed Light Duty units (suitable for light loads). The housings of the units are bright metal zinc plated or completely stainless steel made and they incorporate self cleaning bottom holes and oiled felt sealing system (except SP8-12-15-25). This is available on request on SP 15 and 25 series only. We can also provide ball transfer units with main balls made of AISI 440C, AISI 304, AISI 316, teflon, glass, with various coupling between big and small balls.

Applications

At STR Industries, our ball transfer units facilitate the movement of heavy loads with minimal stress in conveyance applications across all industries. Some of the most common uses for our ball transfer units include:

- CARGO ROLLER DECKS FOR AIR TRANSPORT

- SHEET METAL-WORKING MACHINES

- FOLDING PRESSES

- BALL TRANSFER TABLES

- LIFTING & TRANSPORT EQUIPMENT & PLATFORMS

- MARBLE WORKING MACHINES

- CERAMIC TILES AND BRICKS MACHINES

- TRANSPORTERS FOR CONTAINERS & PLATFORMS

- SLIDING WALLS

- SLIDING DOORS AND WINDOWS

- MOLDING DEVICES

- ROBOTICS

- ELECTRONICS

- AUTOMOTIVE RACKS

- GUILLOTINE PRESSES

- MOULDING MACHINES

- HYDRAULIC PRESSES

- CONVEYORS

A BALL TRANSFER UNIT IS DESIGNED AS SHOWN IN THE PICTURE

The ball transfer units can be assembled horizontally, vertically or ball down, they do not need hard maintenance and are provided with felt sealing (or a plastic on if they have to be exposed to high temperature). Under particular conditions (high humidity, dyes, soaking baths, sea water) the usual correct activity can be damaged; in order to repair these inconveniences, some kinds of ball transfer units have a dirt exit hole in the bottom.

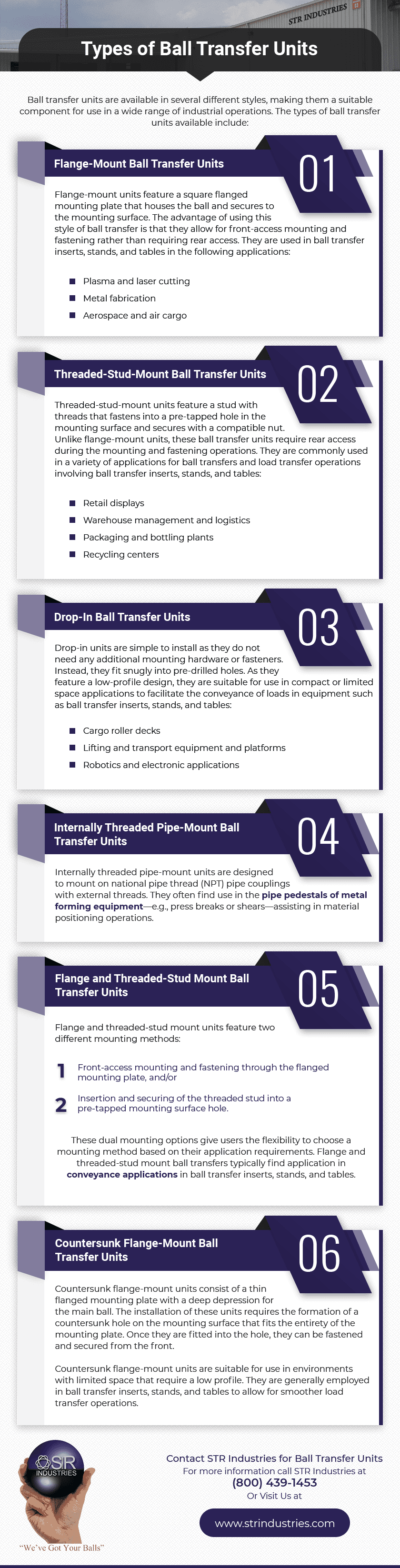

Types of Ball Transfer Units

Ball transfer units are available in several different styles, making them a suitable component for use in a wide range of industrial operations. The types of ball transfer units available include:

Flange-Mount Ball Transfer Units

Flange-mount units feature a square flanged mounting plate that houses the ball and secures to the mounting surface. The advantage of using this style of ball transfer is that they allow for front-access mounting and fastening rather than requiring rear access. They are used in ball transfer inserts, stands, and tables in the following applications:

- Plasma and laser cutting

- Metal fabrication

- Aerospace and air cargo

Threaded-Stud-Mount Ball Transfer Units

Threaded-stud-mount units feature a stud with threads that fastens into a pre-tapped hole in the mounting surface and secures with a compatible nut. Unlike flange-mount units, these ball transfer units require rear access during the mounting and fastening operations. They are commonly used in a variety of applications for ball transfers and load transfer operations involving ball transfer inserts, stands, and tables:

- Retail displays

- Warehouse management and logistics

- Packaging and bottling plants

- Recycling centers

Drop-In Ball Transfer Units

Drop-in units are simple to install as they do not need any additional mounting hardware or fasteners. Instead, they fit snugly into pre-drilled holes. As they feature a low-profile design, they are suitable for use in compact or limited space applications to facilitate the conveyance of loads in equipment such as ball transfer inserts, stands, and tables:

- Cargo roller decks

- Lifting and transport equipment and platforms

- Robotics and electronic applications

Internally Threaded Pipe-Mount Ball Transfer Units

Internally threaded pipe-mount units are designed to mount on national pipe thread (NPT) pipe couplings with external threads. They often find use in the pipe pedestals of metal forming equipment—e.g., press breaks or shears—assisting in material positioning operations.

Flange and Threaded-Stud Mount Ball Transfer Units

Flange and threaded-stud mount units feature two different mounting methods:

- front-access mounting and fastening through the flanged mounting plate, and/or

- insertion and securing of the threaded stud into a pre-tapped mounting surface hole.

These dual mounting options give users the flexibility to choose a mounting method based on their application requirements. Flange and threaded-stud mount ball transfers typically find application in conveyance applications in ball transfer inserts, stands, and tables.

Countersunk Flange-Mount Ball Transfer Units

Countersunk flange-mount units consist of a thin flanged mounting plate with a deep depression for the main ball. The installation of these units requires the formation of a countersunk hole on the mounting surface that fits the entirety of the mounting plate. Once they are fitted into the hole, they can be fastened and secured from the front.

Countersunk flange-mount units are suitable for use in environments with limited space that require a low profile. They are generally employed in ball transfer inserts, stands, and tables to allow for smoother load transfer operations.

Materials Used in Ball Transfer Units

The main balls in ball transfer units may be composed of:

- Stainless steel

- Zinc-plated carbon steel

- Heavy duty nylon (for non-marking applications)

The support balls are manufactured with a high degree of precision, then ground and heat treated to ensure the lowest amount of friction and the smoothest motion for the main ball.

Contact Us Today for Your Ball Transfer Unit Needs

At STR, we have more than five decades of experience providing high quality steel products, including ball transfer units. By partnering with us for your ball transfer unit needs, you can take advantage of our:

- Customization capabilities

- Competitive prices

- Cutting-edge technology

- Commitment to quality and customer service

With locations around the world, we offer top-quality ball transfer units guaranteed to meet your specifications with minimal turnaround. To learn more about how our ball transfer units can facilitate your conveying operations or for assistance selecting a product for your application, contact us today.