Grinding Media

Grinding Media Services

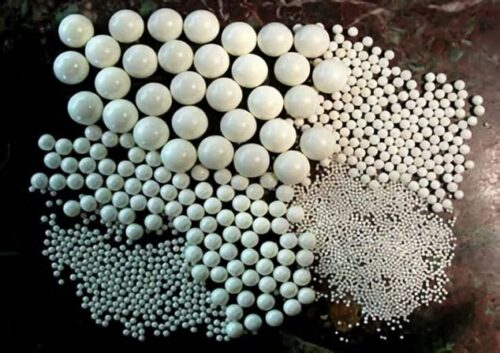

Selecting the proper media for grinding and milling operations is essential. Grinding media is used in these processes to grind or crush material to both reduce particle size and refine material. Grinding media is available in a broad variety of materials, shapes, and sizes. Which media is appropriate depends on the specifics of the intended application.

Mixing, crushing, dispersing, and purifying variable materials generally requires some type of grinding media ball or bead. Various properties influence how the work material is processed and how long the media can be used for. Many facets of grinding media can be customized, such as:

- Material composition

- Density

- Bulk density

- Hardness

- Surface finish

- Color

STR Industries is a professional ball manufacturer and we have been manufacturing media for 30 years. We are TS 16949(auto industry standard, higher than ISO 9001) certified. Our 200,000 square foot facilities produce more than 400 metric tons of balls per month. Our product sizes range from 0.8mm to 80mm in chrome, carbon, stainless steel, plastic and ceramics material.

Our grinding media is approved by customers not only in the ink but also pigment, paste, ferrite and food industries. We have been providing customers worldwide directly with our products saving substantial amount of money. If you are not sure what media you need, we offer free consultations to make sure you get the perfect product for your operation.

Ceramic Media (Beads/Balls)

Next Generation Ceramic Media

Ceramic media is ideal for applications that call for highly efficient grinding with low grinding media abrasion. Applications where mixing and dispersing effects impact the final outcome of a project will benefit from the use of ceramic media.

While steel media is common for grinding in many instances, it cannot be used to manufacture bright colors. Contamination from the steel is also an issue for some product types.

Ceramic beads present a number of benefits, such as:

- Higher density

- Similar performance to steel

- Reduced product contamination

- Ideal for use with white or bright colors

- Longer service life

- Available in nano sizes

At STR, we offer grinding media with ceramic materials such as:

Zirconium Oxide (Zirconia)

Zirconia is used in grinding media, cutting tools, jewelry, refractory materials and a variety of other applications due to beneficial physical properties such as high hardness, strength, toughness, excellent wear resistance, electrical conductivity, and low thermal conductivity.

Zirconia beads make the best use of the structural properties in specific characters of zirconia. The various classifications of zirconia include:

- Fully-stabilized Zirconia (FSZ)

- Partial-stabilized Zirconia (PSZ)

- Tetragonal Zirconia polycrystal (TZP)

- Tetragonal toughened Zirconia (TTZ)

- Zircon (Zirconium silicate)

Featuring high density and exceptional hardness, Yttria Stabilized Zirconia Beads ZY offer higher productivity, longer mill life, and lower long-term operational costs. These 100% round and uniform beads are available in sizes ranging from 0.1–2.7 mm.

Ceria Stabilized Zirconia Beads CZ offer the highest density, optimized wear resistance, and cost effectiveness as an efficient milling media. Available sizes range from 0.3–2.7 mm, and these beads are also guaranteed to be 100% round and uniform.

| Composition | Density g/cm3 | Bulk Density kg/l | Hardness Hv | Color | |

|---|---|---|---|---|---|

| ZY | ZrO2 / Y2O3 | >6.02 | > 3.7 | >1350 | Ivory |

| CZ | ZrO2 / CeO2 | >6.20 | > 3.9 | >1250 | Brown |

Other Grinding Media

| Composition | Density | Bulk Density | Hardness | Color | |

|---|---|---|---|---|---|

| Steel | See steel info | 7.8 | 4.9 | 60-65 RC | Silver |

| Glass | SiO2 | 2.5 | 1.6 | Transparent | |

| Alumina | Al2O3 | 3.8 | 2.2 | 1600 Hv | White |

| Zircon | ZrSiO4 | 3.8 | 2.4 | 1000 Hv | White |

| ZY | ZrO2+Y2O3 | 6 | 3.6 | 1300 Hv | Ivory |

| CY | ZrO2+CeO2 | 6.2 | 3.8 | 1200 Hv | Brown |

Aluminum Oxide (Alumina)

Aluminum oxide is known for high strength and surface area properties, along with corrosion and heat resistance.

- Carbon Steel Ball

Material Available

- Low Carbon: AISI 1008~ AISI 1018

- Medium Carbon: AISI 1045

- High Carbon: AISI 1065~ AISI 1085

AISI Number C % Si % Mn % Mo % P % S % Hardness AISI 1008 0.10 Max 0.30 Max 0.50 Max 0.012 0.07 Max 0.06 Max Case Hardened

HRC 55MinAISI 1015 0.13~0.18 0.10~0.30 0.30~0.60 0.02 0.04max Case Hardened

HRC 55~61AISI 1045 0.43~0.50 0.10~0.30 0.60~0.90 0.025 0.04 Max 0.05 Max Through Hardened

HRC 60 MinAISI 1086 0.83~0.88 0.10~0.30 0.30~0.70 0.04 0.04 Max 0.04 Max Through Hardened

HRC 60 MinChemical Composition

Grade

3 ~ 1000

Size

1.0mm~ 2″

Application

Casters, bicycle parts, light-duty bearing, hardware, toy and etc.

- Chrome Steel Ball

C % Si % Mn % Cr % Cu % S % P % 0.90~1.05 0.15~0.35 0.25~0.45 1.35~1.65 0.3 Max 0.03 Max 0.03 Max Chemical Composition

Density

7.84 g/cm3

Hardness

Through hardened, HRC 60 Min. Grade

5~ 1000 gradeSize

0.5mm~5″

Application

Bearing, Ball Screw, Linear motion guide, Auotomotive parts, Chemical, food processing.

- Stainless Steel Ball

Material Available

- AISI 302~AISI 316

- AISI 420~AISI 440C

AISI

NumberC % Si % Mn % Cr % Ni % Mo % P % S % Character AISI 302 0.15 Max 1.00 Max 2.00 Max 17.0~ 19.0 8.0~ 10.5 0.045 Max 0.03 Max Slightly

magnetic

AusteniticAISI 304 0.07 Max 1.00 Max 2.00 Max 17.0~ 19.0 8.50~ 10.5 0.045 Max 0.03 Max Slightly

magnetic

AusteniticAISI 316 0.07 Max 1.00 Max 2.00 Max 16.5~ 18.5 10.5~ 13.5 2000~ 2.50 0.045 Max 0.03 Max Nonmagnetic

Austenitic

Excellent corrosion

resistanceAISI 420J 0.17~ 0.25 1.00 Max 1.00 Max 12.0~ 14.0 0.045 Max 0.03 Max Magnetic

Hardenable HRC

48 Min fair

corrosion

resistanceAISI 430 0.08 max 1.00 Max 1.00 Max 15.5~ 17.5 0.045 Max 0.03 Max Fair- good

corrosion

resistance

AISI 440C 0.95~ 1.20 1.00 Max 1.00 Max 16.0~ 18.0 0.40~ 0.80 0.04 Max 0.02 Max Fair corrosion

resistance

Hardenable HRC

58 MinChemical Composition

Grade

10~1000

Size

0.5mm~2″

Application

Dispenser valve ball, stainless steel bearing, chemical related application

Industries

Some of the industries that rely on ceramic grinding media include:

- Inks

- Paints

- Advanced ceramics

- Chemical production

- Mining

- Cosmetics

- Pharmaceutical

- Automotive

- Water treatment

STR Industries Grinding Media Capabilities/Production Processes

In addition to ceramic media, we also offer a selection of metallic grinding media. Balls may be made of carbon steel, glass, chrome steel, or stainless steel and range from 0.8–80 mm.

Our grinding media is subjected to a variety of production and inspection processes before being sent to the customer, such as:

- Wire – Inspections are conducted to verify dimensions, composition, and other factors.

- Heading – Advanced controllers such as brankamp are used for precision control over the wire feeding and heading processes.

- Flashing – Includes full parameter control and certification procedures to guarantee process quality and stability.

- Heat treating – Relies on the use of digital controllers to regulate furnace temperature, heating time, and carbon potential. Also continuously records furnace temperatures for tracking purposes.

- Grinding – Each step is tightly monitored and controlled.

- Fine grinding – The final grinding step, fine grinding results in high-quality finished balls in terms of dimension, roundness, and surface finish.

- Cleaning – The balls are washed with an automatic ultrasonic washing machine and hydrocarbon solvents. This simultaneously achieves high levels of cleanliness and imparts anti-corrosion properties.

- Sample quality control – Ball quality is verified with the use of state-of-the-art metrology equipment.

- 100% inspection – The product is only shipped after passing 100% inspection.

Grinding Media From STR Industries

STR Industries has been manufacturing media of various types for 30 years and we are TS 16949 certified for quality assurance. We operate more than 200,000 square feet of facility space that produces more than 400 metric tons of balls per month. Our grinding media is used by customers in sectors ranging from inks and pigments to food and beverage. Some of our customers include BASF, Akzo Nobel, Sun Chemical, and many large mill manufacturers and users.

For more information on our capabilities or available grinding media, please contact us.