What Are Ball Transfer Units?

If you’re handling heavy loads, guiding flat surfaces, or designing a multidirectional conveyor system, chances are you’ve encountered ball transfer units — but what exactly are they?

Ball transfer units (BTUs) are load-bearing components designed to move items smoothly and in any direction. They consist of a main ball sitting on top of several smaller internal balls inside a steel or plastic housing. This design allows objects on top to glide with minimal friction, even when changing direction or position.

You’ll find them in industries like aerospace, packaging, manufacturing, and material handling — wherever flat-bottomed loads need to move across a surface efficiently.

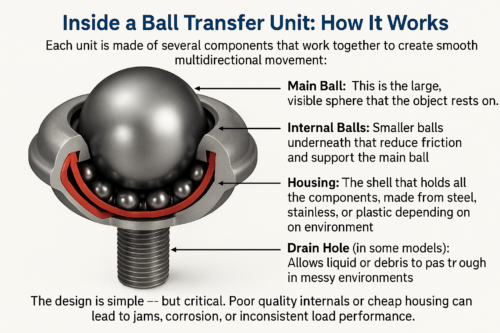

Inside a Ball Transfer Unit: How It Works

Each unit is made of several components that work together to create smooth multidirectional movement:

- Main Ball: The large, visible sphere that the object rests on.

- Internal Balls: Smaller balls underneath that reduce friction and support the main ball.

- Housing: The shell that holds all the components, made from steel, stainless, or plastic depending on the environment.

- Seal & Retainer: Help keep dirt and moisture out, and keep the internal balls in place.

- Drain Hole (in some models): Allows liquid or debris to pass through in messy environments.

The design is simple — but critical. Poor quality internals or cheap housing can lead to jams, corrosion, or inconsistent load performance.

Types of Ball Transfer Units by Housing Material

STR Industries supplies several types of BTUs, depending on the application, load size, and environment:

🔹 Hardened Steel Housing

- Best for heavy-duty loads, high impact, and rugged use

- Common in mechanical conveyors, press lines, or airport handling units

- Offers maximum durability, especially in harsh industrial settings

🔹 Pressed Metal Sheet Housing

- Good for medium or light loads

- More affordable than turned steel models

- Used in packing stations, transport tables, or adjustable workbenches

🔹 Plastic Housing or Components

- Designed for clean environments like food, pharmaceutical, or electrical industries

- Non-corrosive, food-safe (NSF/ANSI 51), and compliant with EC 10/2011

- Excellent for insulating applications or where metal contact must be avoided

Each version can be combined with different types of main balls (chrome, stainless, plastic) depending on your operational needs.

Common Use Cases for Ball Transfer Units

Ball transfer units are versatile — which is why they’re used across so many industries. You’ll find them in:

- Airport cargo systems

- Sheet metal processing machinery

- Pallet and container racks

- Marble and ceramic handling

- Robotics and automation systems

- Elevating platforms

- Sliding walls, doors, and gates

- Automotive assembly lines

- Food and pharmaceutical production lines (using plastic BTUs)

If your process requires items to move quickly, smoothly, and with minimal operator effort — this is where BTUs shine.

How to Choose the Right Ball Transfer Unit

When selecting a ball transfer unit, don’t just look at price. You’ll want to match the design to your operating environment, material compatibility, and load requirements. Here are a few things to consider:

- Load Rating: What is the heaviest item the unit will support? Heavier loads require steel housings and larger diameter main balls.

- Environment: Is there moisture, chemical exposure, or food contact? Go with stainless or plastic materials accordingly.

- Mounting Type: Threaded pin, flange, seeger clip, recessed mount — each install method serves a different purpose.

- Temperature Range: Standard BTUs work up to 100°C. For hotter environments, use all-metal designs with no internal seal.

- Smoothness vs. Impact Resistance: For delicate motion (like packaging lines), plastic might do the job. For factory floor abuse, steel is your best bet.

Still not sure? We can help you compare your specs with our range of options to get a perfect fit.

Final Word

Ball transfer units may look simple, but choosing the right one can make or break your system’s reliability and efficiency. Whether you’re moving small parts or multi-ton loads, STR Industries offers precision-built BTUs for every application — from cleanrooms to cargo floors.

📞 Need Help Selecting the Right Unit?

We’re more than just a parts supplier — we’ll help you choose the right housing, material, and mounting option to match your environment and budget.

👉 Contact STR Industries for quotes, catalog access, or a custom consultation.