Different Types of Steel Balls That Meet Your Needs

- Steel Balls

Steel balls are spherical components used as rolling mechanisms in rotary motion components such as bearings, tooling, wheels, but there are other use for steel balls such as grinding or burnishing media, toys and more. There are many sizes and gauges used in a variety of applications.

Selecting the Right Steel Ball

When sourcing steel balls, consider your application and the function you need the ball to perform. Various options are available when creating steel balls and bearing balls, so you will need to consider the size and materials.

- Steel balls are available in standard and metric sizes, so determine which is most appropriate for your purpose. Standard-sized steel balls are typically less expensive and normally available for immediate delivery. However, STR Industries will design custom sizes upon request.

- Material choice dictates the physical characteristics of the steel ball, such as hardness, magnetic properties, and oxidation resistance. Steel balls are available in low carbon (1015, 1018), high carbon (1065,1085), chrome (52100), and stainless steel (302, 304, 316, 420, and 440). The intended application will play a significant role in determining the appropriate material choice.

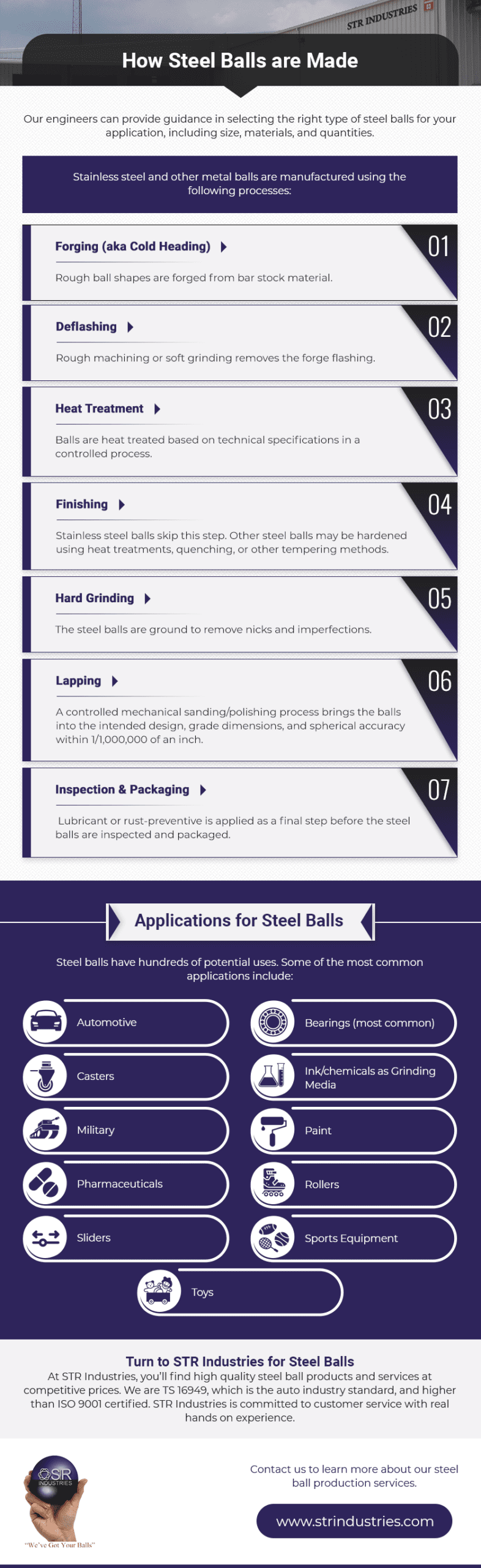

How Steel Balls are Made

Our engineers can provide guidance in selecting the right type of steel balls for your application, including size, materials, and quantities.

Stainless steel and other metal balls are manufactured using the following processes:- Forging aka cold heading. Rough ball shapes are forged from bar stock material.

- Deflashing. Rough machining or soft grinding removes the forge flashing.

- Heat treatment. Balls are heat treated based on technical specifications in a controlled process.

- Finishing. Stainless steel balls skip this step. Other steel balls may be hardened using heat treatments, quenching, or other tempering methods.

- Hard Grinding. The steel balls are ground to remove nicks and imperfections.

- Lapping. A controlled mechanical sanding/polishing process brings the balls into the intended design, grade dimensions, and spherical accuracy within 1/1,000,000 of an inch.

- Inspection & Packaging. Lubricant or rust-preventive is applied as a final step before the steel balls are inspected and packaged.

Applications for Steel Balls

Steel balls have hundreds of potential uses. Some of the most common applications include:

- Automotive

- Bearings (most common)

- Casters

- Ink/chemicals as grinding media

- Military

- Paint

- Pharmaceuticals

- Rollers

- Sliders

- Sports Equipment

- Toys

Carbon Steel Ball

Material Available

- Low Carbon: AISI 1008~ AISI 1018

- Medium Carbon: AISI 1045

- High Carbon: AISI 1065~ AISI 1085

AISI Number C % Si % Mn % Mo % P % S % Hardness AISI 1008 0.10 Max 0.30 Max 0.50 Max 0.012 0.07 Max 0.06 Max Case Hardened

HRC 55MinAISI 1015 0.13~0.18 0.10~0.30 0.30~0.60 0.02 0.04max Case Hardened

HRC 55~61AISI 1045 0.43~0.50 0.10~0.30 0.60~0.90 0.025 0.04 Max 0.05 Max Through Hardened

HRC 60 MinAISI 1086 0.83~0.88 0.10~0.30 0.30~0.70 0.04 0.04 Max 0.04 Max Through Hardened

HRC 60 MinChemical Composition

Grade

3 ~ 1000

Size

1.0mm~ 2″

Application

Casters, bicycle parts, light-duty bearing, hardware, toy and etc.

Chrome Steel Ball

C % Si % Mn % Cr % Cu % S % P % 0.90~1.05 0.15~0.35 0.25~0.45 1.35~1.65 0.3 Max 0.03 Max 0.03 Max Chemical Composition

Density

7.84 g/cm3

Hardness

Through hardened, HRC 60 Min. Grade

5~ 1000 gradeSize

0.5mm~5″

Application

Bearing, Ball Screw, Linear motion guide, Automotive parts, Chemical, food processing.

Stainless Steel Ball

Material Available

- AISI 302~AISI 316

- AISI 420~AISI 440C

AISI

NumberC % Si % Mn % Cr % Ni % Mo % P % S % Character AISI 302 0.15 Max 1.00 Max 2.00 Max 17.0~ 19.0 8.0~ 10.5 0.045 Max 0.03 Max Slightly

magnetic

AusteniticAISI 304 0.07 Max 1.00 Max 2.00 Max 17.0~ 19.0 8.50~ 10.5 0.045 Max 0.03 Max Slightly

magnetic

AusteniticAISI 316 0.07 Max 1.00 Max 2.00 Max 16.5~ 18.5 10.5~ 13.5 2000~ 2.50 0.045 Max 0.03 Max Nonmagnetic

Austenitic

Excellent corrosion

resistanceAISI 420J 0.17~ 0.25 1.00 Max 1.00 Max 12.0~ 14.0 0.045 Max 0.03 Max Magnetic

Hardenable HRC

48 Min fair

corrosion

resistanceAISI 430 0.08 max 1.00 Max 1.00 Max 15.5~ 17.5 0.045 Max 0.03 Max Fair- good

corrosion

resistance

AISI 440C 0.95~ 1.20 1.00 Max 1.00 Max 16.0~ 18.0 0.40~ 0.80 0.04 Max 0.02 Max Fair corrosion

resistance

Hardenable HRC

58 MinChemical Composition

Grade

10~1000

Size

0.5mm~2″

Application

Dispenser valve ball, stainless steel bearing, chemical related application

- Bearing Balls

STR Industries manufactures millions of bearing balls. The balls come in many different grades, as defined by the American Bearing Manufacturers Association (ABMA), which defines the precision of balls. Predictable uniformity, or repeatability, in the manufacturing process is crucial to ensuring consistent performance of STR’s bearing balls.

Bearing balls are a type of rolling-element bearing that uses balls to maintain the separation between moving parts. Bearing balls are at the heart of almost every product with a rotating shaft. They are used in bicycles, blenders, washing machines, fans, and many other products.

Bearing Balls and STR Industries

STR Industries has more than 50 years of experience in the manufacturing of steel ball for large and small projects alike. Our customers are located throughout the United States, Europe, and Asia.

Our TS 16949 certification demonstrates our commitment to quality management and continuous improvement, emphasizing defect prevention in design, development, and production with an added commitment to the reduction of waste in all aspects of production. We offer inspection on 100% of our products. Our pricing is very competitive – on average, our customers save 20-30% on manufacturing costs.

If you are in an industry that uses steel balls or bearing balls, STR Industries has a solution for you. Please contact us with the details of your project.

Available Grades and Sizes:

Grade Size Range (inches) 3 025" - 3/16" 5 .025" - 1 1/2" 10 1/32" - 2 1/2"

16 1/32" - 2 1/2" 24 1/32" - 2 1/2" Grade Size Range (inches) 48 1/32" - 2 1/2" 100 1/32" - 4 1/2" 200 1/32" - 4 1/2"

1000 1/32" - 4 1/2"

We can offer balls for any unique applications, such as:

- Games (pinball machines)

- Toys

- Weights

- Medicine Balls

- Dent Removal