Design and Application of Our Ball Transfer Units

Ball Transfer Units

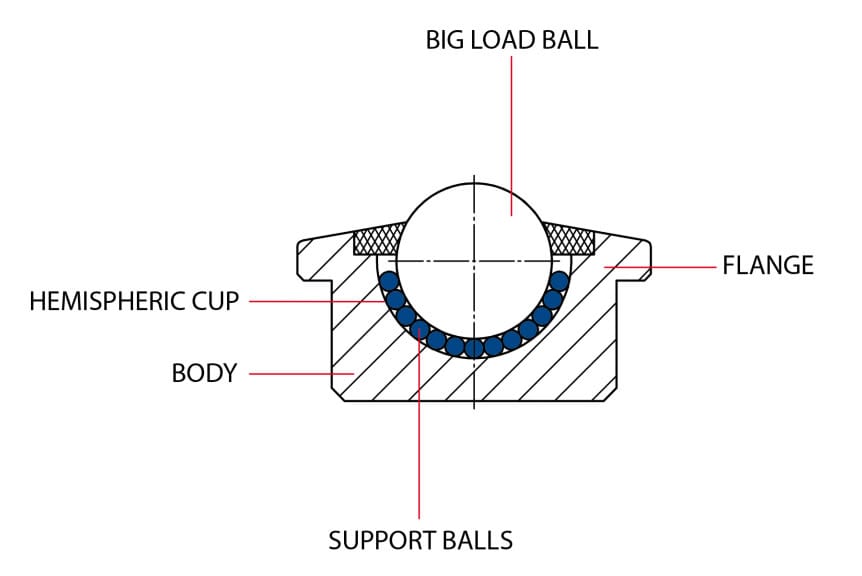

At STR Industries, we supply high-quality ball products at competitive prices — including precision-engineered ball transfer units. Each unit features a large central ball mounted within a housing and supported by smaller bearings, enabling smooth, omni-directional movement of heavy loads.

These units are ideal for use in industrial applications like warehouses, packaging lines, fabrication shops, and logistics centers. All balls are ground and heat treated to reduce friction and ensure smooth, controlled movement at speeds up to 2 m/sec.

Our catalog includes ball sizes from 8 mm to 90 mm, with load capacities ranging from 15 kg to 2,000 kg, in materials such as steel, stainless steel, and polyacetal plastic.

Available Ball Diameters

- Small: 8 mm, 13 mm, 15 mm, 17 mm, 18 mm

- Medium: 23 mm, 24 mm (± tolerances), 25.4 mm, 28 mm, 33 mm, 36 mm (± tolerances), 39 mm

- Large: 45 mm (± tolerances), 48.2 mm, 50 mm, 62 mm (± tolerances), 66.4 mm

- Extra-Large: 100 mm (± tolerances)

We offer two main types: Machined Heavy Duty units for high shock loads and extended use, and Pressed Light Duty units for lower weight requirements. Housings are either zinc-plated or stainless steel, and feature self-cleaning holes and optional felt seals (except for SP8-12-15-25 models).

Main ball materials available: AISI 440C, AISI 304, AISI 316, Teflon, and glass.

Popular Models & Starting Prices

- K1322: Stud-mounted unit – from $38.70

- K0749: Mini unit – from $68.88

- K0760: Steel housing – from $11.33

- K0761: Steel housing, plastic ball – from $12.18

- K1827: Plastic housing – from $16.96

- K0762: Undersprung unit – from $96.08

- K0763: Solid steel housing – from $686.52

- K1323: Heavy-duty – from $104.49

- K1325: Outdoor heavy-duty – from $115.60

- K0764: Fastening holes, no housing – from $25.55

- K0765: Spring clips – from $27.13

- K1734: Clampable steel ball – from $171.68

Available Outside Diameters

- Small: 8 mm, 13 mm, 15 mm, 17 mm, 18 mm

- Medium: 23 mm, 24 mm, 28 mm, 31 mm, 32.1 mm

- Large: 45 mm, 50 mm, 55 mm, 62 mm, 63 mm

- Extra-Large: 75 mm, 85 mm, 117 mm

DK Measurement Options

- Small to Medium: 4.8 mm, 6.4 mm, 7.9 mm, 9.6 mm, 12.7 mm

- Medium to Large: 15.8 mm, 19 mm, 22 mm, 22.2 mm

- Largest: 30 mm, 44.5 mm, 45 mm, 57.1 mm

Applications

Our ball transfer units simplify the movement of heavy materials and reduce manual labor in industrial settings. Common applications include:

- Cargo roller decks for air transport

- Sheet metal-working machines

- Folding presses

- Ball transfer tables

- Lifting and transport platforms

- Marble and ceramic tile machines

- Container transporters

- Sliding doors, walls, and windows

- Molding devices and machines

- Robotics and electronics handling

- Automotive racks and guillotine presses

- Hydraulic presses and conveyors

How Ball Transfer Units Are Designed

Ball transfer units can be mounted horizontally, vertically, or ball-down depending on the application. They require little maintenance and typically come with felt seals—or plastic seals when exposed to high temperatures.

In harsh environments such as high humidity, dye baths, soaking solutions, or saltwater exposure, performance can degrade. To mitigate these issues, certain models include a bottom-mounted dirt exit hole to help maintain reliability.

Available Height Options

Ball transfer units are available in a wide range of heights to meet different application needs and equipment requirements.

Common Height Ranges

- 1 to 10 mm: Ideal for lightweight or compact applications.

- 10 to 20 mm: Suitable for standard medium-duty transfers.

Moderate Height Options

- 20 to 30 mm: Great for moderate loads and frequent use.

- 30 to 40 mm: Ideal for applications needing more durability and height.

High-Clearance, Heavy-Duty Heights

- 40 to 60 mm: Designed for heavy loads and rugged environments.

- Over 60 mm: Used in specialized scenarios that demand extra clearance or load-bearing capacity.

These height options allow engineers and designers to match ball transfer units to the precise needs of their operations—whether light-duty or industrial-grade.

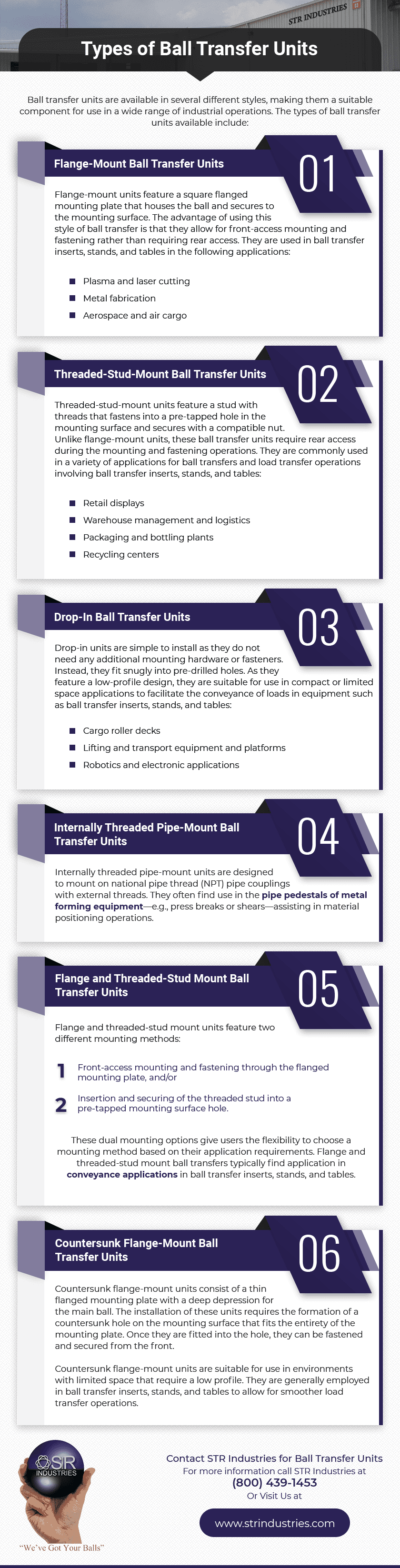

Types of Ball Transfer Units

Ball transfer units are available in several different styles, making them a suitable component for a wide range of industrial operations. The types include:

Flange-Mount Ball Transfer Units

These feature a square flanged mounting plate that houses the ball and secures to the mounting surface. They allow for front-access mounting and are used in:

- Plasma and laser cutting

- Metal fabrication

- Aerospace and air cargo

Threaded-Stud-Mount Ball Transfer Units

These have a threaded stud that fastens into a pre-tapped hole, requiring rear access. Common in:

- Retail displays

- Warehouse logistics

- Packaging and bottling

- Recycling centers

Drop-In Ball Transfer Units

These fit snugly into pre-drilled holes without fasteners, ideal for compact spaces:

- Cargo roller decks

- Lifting and transport equipment

- Robotics and electronics

Internally Threaded Pipe-Mount Units

Mount onto NPT pipe couplings and are used in pipe pedestals of metal forming equipment (e.g., press brakes or shears).

Flange and Threaded-Stud Mount Units

Offer dual mounting: front-access via flange or rear-access via threaded stud. Often used in conveyance systems.

Countersunk Flange-Mount Units

Feature a thin flange and deep ball depression for low-profile installations. Ideal for tight spaces needing smooth load transfer.

Materials Used in Ball Transfer Units

Main ball options include:

- Stainless steel

- Zinc-plated carbon steel

- Heavy-duty nylon (non-marking)

Support balls are ground and heat-treated for low friction and smooth operation.

Handle Types & Starting Prices

Explore available types and price ranges:

Ball Transfer Units

- Steel Housing with Plastic Ball: from $12.18

- Plastic Housing: from $16.96

- Undersprung Units: from $96.08

- Solid Steel Housing: from $686.52

Heavy-Duty Options

- Heavy Duty: from $104.49

- Outdoor Suitable: from $115.60

Specialized Options

- Fastening Holes Only: from $25.55

- With Spring Clips: from $27.13

- Clampable Steel Ball: from $171.68

Additional Components

- Tolerance Rings: from $1.94

Prices vary based on material and configuration.